Introduction to NMP wastewater treatment

N-methalpylpyrrolidone (N-Methylpyrrolidone), referred to as NMP, is an organic matter. The chemical formula is C5H9NO, which is colorless to pale yellow transparent liquid. Various organic solvents such as acetone and ester, marinated hydrocarbons, and aromatics are completely mixed with all solvents.

NMP is a polar or intangible organic solvent. It has the characteristics of high boiling point, strong solubility, low viscosity, chemical stability and good thermal stability. In the electronics industry, it is often used in the electrode coating of lithium battery, which can effectively dissolve electrode materials; in the chemical field, it is an excellent extractant; in the coating and ink industry, it also plays an important role as a solvent. However, the wastewater produced during the use of NMP is one of the difficulty in industrial wastewater. If it is not handled properly, it will cause serious pollution to the environment. Therefore, it is important to understand NMP wastewater treatment.

1. NMP production process

01 γ -butbl (GBL) and methylemine as the raw material

Under a certain temperature and pressure, GBL and methylide react. First of all, the amino group of the amino group attack GBL is formed to form an intermediate product, and then the nMP is generated by the molecular discharge to generate NMP. The reaction is usually performed in the liquid phase, and a suitable catalyst is required to speed up the reaction rate and increase the yield. For example, the selection of specific alkaline catalysts can effectively promote the reaction.

02 reaction condition control

The reaction temperature is generally controlled at 150-2 ° C, and the pressure is maintained at 2-5MPa. The right temperature and pressure can ensure both the response rate and the selectivity of the product. The reaction time is usually 3-5 hours. The reaction ending is determined by the consumption of raw materials and products in the reaction system.

03 Product separation and refining

After the reaction is over, first separate the unresponsive raw materials and by -products by decompression distillation, and then reformed the thick NMP to further purify and obtain a high -purity NMP product.

2. NMP wastewater source

01 Washing process during the production process

After NMP production is completed, in order to remove the remaining impurities and catalysts in the product, water washing operations will be performed. This part of water washing water contains a small amount of NMP, reacting by -products, and residual catalysts to form waste water.

02 Device cleaning

When production equipment is maintained and replaced with regular maintenance and replacement, it needs to be cleaned. The water used during the cleaning process will contact the NMP remaining in the inner wall of the device to generate NMP wastewater. The frequency and strength of cleaning are different, and the amount of wastewater is also different.

03 Lithium battery industry

During the coating of lithium battery electrodes, NMP is used as a solvent for dissolving electrode materials. After coating, NMP will be removed through drying and other processes. However, some NMP will be discharged with the exhaust gas during the drying process. After the water spraying, these exhaust gas will be sprayed, and the spray wastewater formed contains NMP. In addition, the clean water of the lithium battery production workshop will also become a source of wastewater due to contact with the sprinkled NMP material.

04 Chemical production

During the production of aramid, NMP is often used as a solvent for dissolving polymer or auxiliary reactions. For example, in the synthesis of the medium and the aramidine, in order to make the aggregate reaction go smoothly, the monomer needs to be dissolved in the NMP solvent system. After the reaction is completed, when the product is separated and washed, a large amount of wastewater containing NMP will be generated. In addition, in the process of rear treatment of aramite fibers, such as washing and stretching, water used to clean the surface of fiber surface will also contain NMP. Similarly, in other chemical products production, if NMP is used as a reactive solvent or extraction agent, NMP wastewater will be generated in the product separation, refining, and equipment cleaning.

Third, the characteristics of wastewater

01 concentration is high

NMP itself is an organic matter that has high chemical oxygen demand in water. At the same time, the wastewater may also contain other organic impurities, which further increases the COD value. Generally, the COD of NMP wastewater exceeds 5000 mg/L, or even higher, which makes the biologicalization of wastewater poor and high requirements for subsequent processing processes. In addition, NMP wastewater also contains a large number of nitrogen rings organic objects, resulting in its ammonia nitrogen concentration is also very high, usually more than 500mg/L.

02 Biotoxicity

NMP has certain toxicity for microorganisms and will inhibit the growth and metabolic activities of microorganisms. When the NMP concentration in wastewater is high, the enzyme activity of microorganisms will be reduced, affecting its ability to decompose other pollutants in the wastewater, and cause biological treatment process to be difficult to run normally.

03 Stable stability

The NMP structure is relatively stable and it is difficult to break down in the natural environment. This means that without effective treatment, NMP will exist in the water body for a long time, which will continue to pose a threat to the ecological environment.

04 complicated ingredients

In addition to NMP, wastewater may contain residue catalysts, reaction glyworia, and other additives in the production process. These ingredients are intertwined and increased the difficulty of wastewater treatment.

3. Processing process

NMP wastewater treatment is mainly divided into three stages, namely pre -processing, biochemical processing and in -depth treatment. In the company's NMP wastewater treatment case, we adopt a treatment process mainly based on biochemical treatment, including anaerobic biological treatment and A/O. Nitrogen removal process.

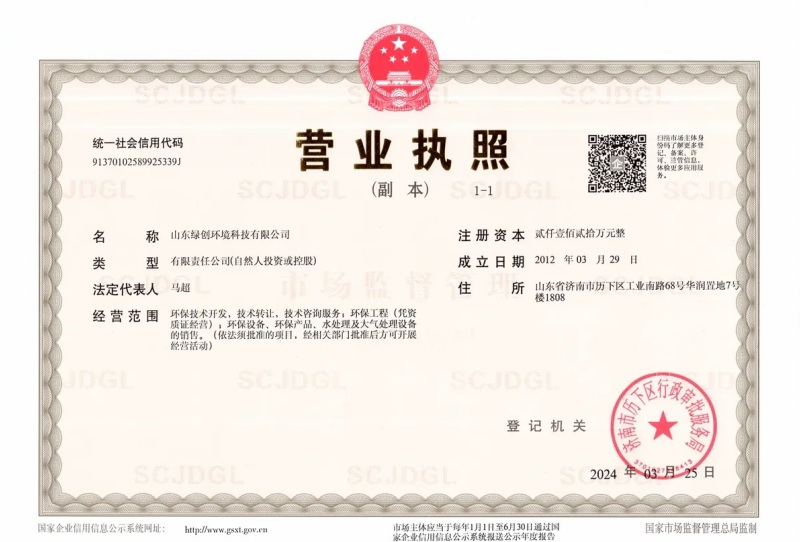

The company's NMP wastewater treatment project

01 anaerobic biological treatment

As an important part of the entire treatment process, anaerobic biological treatment cleverly uses anaerobic microorganisms to degrade organic substances in hypoxic or micro -oxygen environments. These anaerobic microorganisms grow and reproduce under unique survival conditions, and do not require extra excess oxygen supply, which greatly reduces energy consumption costs. In the process, not only can organic pollutants break down efficiently, but also produce highly valuable by -products -methane gas, which can be used as energy recovery and realizes the secondary conversion of resources.

In practical applications, the UASB reactor has become a commonly used device for anaerobic treatment with its outstanding characteristics. It has a strong adaptability for different water quality conditions and can operate stably in the environment of high concentration of organic wastewater. Its structure is simple, easy to operate and maintains, the construction cost is relatively low, and the technology is mature and reliable, providing solid hardware support for anaerobic biological treatment.

02A/O process

A/O process, that is, ANOXIC/OXIC Process, is a biomarry process specially targeted at ammonia nitrogen and nitrite nitrogen wastewater. This process cleverly combines hypoxia and aerobic conditions, giving full play to the synergistic role of different microbial communities, and gradually converting nitrogen in wastewater into nitrogen, thereby achieving the goal of high -efficiency nitrogen removal.

The A/O process is widely used in the field of industrial wastewater with ammonia nitrogen and organic matter with its efficient, economical, and simple characteristics, and it also occupies an important position in NMP wastewater treatment. Through the fine treatment of the A/O process, the ammonia nitrogen content in NMP wastewater has been significantly reduced, and the decomposition rate of organic matter is greatly improved to ensure that the wastewater reaches strict emission standards.

Not only that, the A/O process also has excellent compatibility, which can be organically combined with other technologies such as anaerobic treatment and materialized treatment to further improve the overall treatment effect of wastewater. In the actual operation process, according to the specific water quality status and processing requirements of NMP wastewater, the operating parameters of the A/O process must be accurately adjusted, such as the duration of the hypoxia and the oxygen stage, dissolved oxygen concentration, pH value, temperature, etc. Key parameters need to be strictly controlled. At the same time, the water quality parameters are regularly monitored, and the operating parameters are optimized in a timely manner based on the monitoring results to ensure the stability and efficient operation of the processing system.

Over the years, the company has been responsible for NMP wastewater treatment projects such as Changxin Chemistry with its deep technical accumulation and the persistence of environmental protection undertakings. It has accumulated a lot of experience in this type of wastewater treatment and obtained unanimous praise from customers.

In the future, we will keep in mind that we will persist in customer -centric, to create personal value for customers, and use green standards to cast the mission of high -quality environmental protection engineering services. Provide customers with more efficient, greener, and cost -effective solutions!