A comprehensive overview of industry trends: Green alcohols and water treatment

Green methanol refers to methanol produced using renewable energy sources (such as solar and wind power) and biomass resources. Its core lies in achieving low-carbon or even net-zero emissions throughout the production process and the entire life cycle. It is mainly produced through technologies such as biomass fermentation and renewable electricity-to-hydrogen synthesis. As a clean fuel and chemical raw material, it aims to replace fossil fuels, reduce greenhouse gas emissions, and is an important part of achieving energy transition.

Simply put, traditional methanol (methanol is CH3OH, a simpler alcohol) is a fossil fuel product, while chloroethanol is "made" using green energy and sustainable raw materials. It is an environmentally friendly form of methanol and aims to become a key clean fuel in the energy transition.

I. The Rise of a Trillion-Yuan Industry: The Core Logic Behind the Explosive Growth of Green Alcohol Projects

The green alcohol industry is at a critical stage of development driven by the global trend of decarbonization in the shipping industry. Although the International Maritime Organization (IMO) has recently encountered setbacks in the process of resolving the International Shipping Net Zero Framework, the long-term direction and value of the industry remain clear.

1. Short-term adjustments and long-term certainty of rules

Recently, IMO member countries have had significant disagreements on the specific details of the Net Zero Framework. At a special meeting on October 17, 2025, they voted to suspend the review and adoption of the amendment for one year. This means that the vote originally scheduled for October 2025 and the implementation timeline for 2027 will be postponed accordingly.

The IMO voted to postpone the vote on the International Shipping Nets Zero Framework for another year.

Although this adjustment has brought short-term uncertainty and may affect the pace of some investment decisions, it has not changed the global shipping industry's strategic goal of achieving net-zero emissions in 2050. More importantly, the two core driving forces of regional regulations and market demand have not been "delayed":

The EU has already taken the lead: the shipping industry has been included in the EU ETS (EU Carbon Market) since 2024, and failure to comply will result in penalties; at the same time, the FuelEU Maritime regulation has set clear greenhouse gas intensity reduction targets. This means that even if the globally unified rules are delayed, ships entering EU waters will still need to comply with stricter emission reduction regulations.

Market demand is already anchored: ship orders and the construction of green fuel supply chains are based on asset operation cycles spanning decades. Globally, there are over 400 methanol-powered vessels (including orders), corresponding to a huge potential demand for green methanol. This forms a solid foundation for green methanol demand.

2. The Current Situation and Opportunities of Supply and Demand Imbalance

The temporary adjustment to the policy framework has not alleviated the fundamental contradiction of a severe supply shortage in the green alcohol market. According to industry data, the current global shipping industry's demand for green alcohol is approximately 6 million tons, but the actual available marine fuel supply is only about 100,000 tons. The supply bottleneck mainly stems from the long project construction cycle (approximately 2.5-3 years) and the EU's stringent sustainable fuel certification threshold.

Therefore, with demand certain while supply release is slow, the supply-demand imbalance will persist for the next few years. Companies that first achieve economies of scale, obtain international certifications, and possess cost advantages will gain a significant market and profit advantage in this round of green transformation. According to the Futures Daily, as of August 2025, 173 green alcohol projects have been signed/registered in China, with a planned total capacity exceeding 53 million tons per year, demonstrating the industry's strong confidence in the future market.

II. Green alcohol production process and technical route

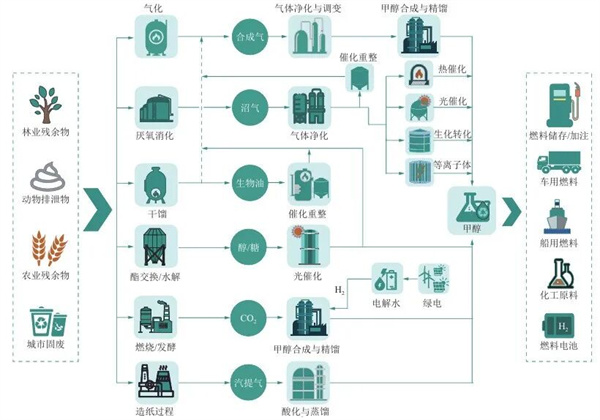

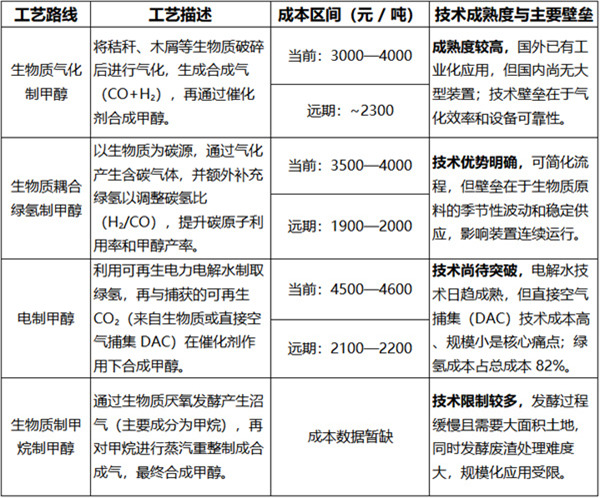

The midstream production process of green methanol involves diverse technological routes, mainly including biomass conversion and electro-methanol production. Currently, there is no single better technological route, and each route differs significantly in terms of cost, maturity, and resource dependence.

Simplified diagram of biomass green methanol production technology route

Biomass gasification route: accounting for 80%-90%, it is the current mainstream and has a lower cost of about 3,800 yuan/ton.

Biomass fermentation route: cost is only 2,000-3,000 yuan/ton, and it will enter the construction and production stage in 2026, with rapid development potential.

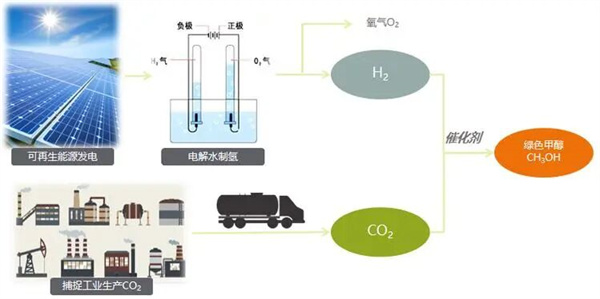

Simplified diagram of the electro-methanol production technology route

The electro-methanol route accounts for about 10% of the total, relies on green hydrogen, and costs about 5,000 yuan/ton. However, it is currently constrained by the costs of green hydrogen and carbon capture. In the future, as the cost of green hydrogen decreases (accounting for 82% of the total cost of electro-methanol), it is expected to become the long-term mainstream.

III. Sources of wastewater from chlorophyll production

The generation of wastewater from chlorol production is deeply intertwined with the core process route, raw material characteristics, and auxiliary production processes. While the sources of wastewater differ significantly across different technologies, they are generally concentrated in raw material treatment, the reaction process, product separation, and auxiliary systems, as detailed below:

1. Wastewater sources specific to biomass routes

Raw material pretreatment wastewater: Washing wastewater generated during the pretreatment stages of biomass raw materials (straw, sawdust, livestock manure, etc.) in the washing, crushing, and drying processes. It mainly contains silt, soil particles, soluble organic matter (such as cellulose and hemicellulose decomposition products), and small amounts of lignin and tannins carried by the raw materials. Leachate wastewater formed during raw material storage due to rain and moisture absorption is mainly composed of suspended solids (SS) and soluble carbohydrates, with a COD concentration of approximately 1000-3000 mg/L. The discharge volume is approximately 0.3-0.5 times the raw material treatment volume (by mass).

Wastewater from gasification/fermentation processes: Phenolic wastewater generated during the syngas cooling and washing stages of biomass gasification to methanol production is the main source of wastewater for this route. It contains phenols (phenol, cresol, etc., concentration of approximately 500-2000 mg/L), aldehydes (formaldehyde, acetaldehyde, concentration of approximately 100-300 mg/L), cyanide (approximately 5-20 mg/L), and a small amount of tar from gasification byproducts. Wastewater from washing fermentation residues and solid-liquid separation in the biomass fermentation route is rich in undegraded sugars (glucose, xylose), proteins, amino acids, and fermentation metabolites (such as organic acids and alcohols). The ammonia nitrogen concentration can reach 100-500 mg/L, and the COD concentration is as high as 10000-50000 mg/L. In the biomass-coupled green hydrogen route, the equipment cleaning wastewater from the green hydrogen preparation stage (water electrolysis system) contains a small amount of electrolytes (such as KOH, H₂SO₄) and catalyst dust.

Product separation wastewater: The distillation residue produced during the methanol distillation and purification process contains high concentrations of refractory organic matter (such as heavy alcohols and esters) and a small amount of methanol residue (concentration of about 500-1000mg/L). The COD concentration is about 8000-15000mg/L, and the emission volume is about 0.8-1.2 times the amount of green alcohol products.

2. Specific wastewater sources for the electro-methanol production route

CO₂ capture system wastewater: Wastewater generated during the regeneration and washing of the absorbent in a direct air capture (DAC) system. It contains trace amounts of absorbent (such as amines and alkali solutions) and dissolved CO₂, has a weakly acidic pH (4.5-6.0), a COD concentration of approximately 300-800 mg/L, and contains organic amine pollutants (concentration approximately 50-100 mg/L), exhibiting some biotoxicity.

Wastewater from green hydrogen production: The circulating cooling drainage of the water electrolysis system for green hydrogen production contains chemical agents such as organophosphorus compounds and bactericides (such as quaternary ammonium salts), with SS concentration of about 50-100 mg/L and total phosphorus concentration of about 10-30 mg/L. Wastewater from cleaning the electrolytic cell contains a small amount of heavy metal ions (such as Ni and Fe, with a concentration of about 0.5-2 mg/L) and electrolyte residues.

3. Wastewater sources from general auxiliary systems

Equipment cleaning wastewater: Wastewater generated from the periodic cleaning of production equipment (reactors, pipelines, storage tanks, distillation columns), containing residual methanol, catalyst dust (such as copper-based and zinc-based catalysts) and a small amount of reaction byproducts. The COD concentration is about 2000-5000 mg/L, and the pH value fluctuates greatly (3.0-11.0). The discharge volume is related to the cleaning frequency (usually 1-2 times per month, with a single discharge volume of about 50-200 m³).

Floor washing and domestic wastewater: Workshop floor washing wastewater contains raw materials and product residues leaked from equipment, with a COD concentration of approximately 500-1500 mg/L; Domestic wastewater from factory employees contains conventional pollutants such as COD, ammonia nitrogen, and suspended solids, with lower concentrations (COD approximately 200-300 mg/L), and the discharge volume is related to the number of employees (approximately 100-150 L/day per person).

IV. Characteristics of Wastewater

The composition of chlorol production wastewater varies considerably depending on the process route, but based on the commonalities of raw material characteristics and production processes, its core characteristics exhibit significant patterns, as follows:

1. The pollutants have complex compositions and are highly toxic.

The wastewater contains a variety of organic compounds that are difficult to degrade: it contains methanol, phenols, aldehydes, organic acids, organic amines, heavy alcohols and other organic compounds. Among them, phenols (especially polyphenols), aldehydes and organic amines are difficult to degrade and have strong chemical stability, making them difficult to completely degrade by conventional biological treatment. Some components (such as phenol concentrations exceeding 50 mg/L) have significant biotoxicity, which can inhibit the respiration, metabolism and reproduction of microorganisms, leading to a decrease in the efficiency of the biological treatment system or even its failure.

Large pollutant concentration span: COD concentrations from different wastewater sources vary greatly, from 200mg/L in domestic wastewater to 50,000mg/L in fermentation separation wastewater, a span of 250 times; ammonia nitrogen concentration fluctuates between 10-500mg/L, total phosphorus concentration between 0.5-30mg/L, and suspended solids (SS) concentration between 50-2000mg/L among them, bringing challenges to the adaptability of the treatment process.

Contains characteristic pollutants: Different routes contain specific characteristic pollutants. Wastewater from the biomass gasification route contains toxic inorganic substances such as thiocyanate and cyanide; wastewater from the electro-methanol production route contains organic amines and heavy metal ions; wastewater from the fermentation route contains high concentrations of ammonia nitrogen and organic acids. These characteristic pollutants require targeted treatment to meet standards.

2. Large fluctuations in water quality and quantity

Water volume fluctuations: Significantly affected by the seasonality of raw material supply. For example, during the straw harvesting season (autumn), when biomass raw materials are processed intensively, wastewater discharge increases by 30%-50% compared to the off-season. During equipment cleaning and maintenance, wastewater discharge may suddenly reach peak levels (the wastewater discharge from a single cleaning can be 2-3 times the average daily discharge). The electro-methanol production route is affected by the stability of renewable power supply, and the start-up and shutdown of the water electrolysis system will cause fluctuations in wastewater discharge.

Water quality fluctuations: When the same treatment system receives wastewater from different sources (such as a mixture of pretreated wastewater and fermentation wastewater), COD, pH value, and concentration of toxic substances will fluctuate drastically. For example, after biomass gasification wastewater is mixed with domestic wastewater, the COD concentration may drop sharply from 5000 mg/L to 1000 mg/L, and the pH value may drop from 10.0 to 7.0. Such fluctuations will disrupt the stability of the treatment process, especially since biological treatment systems are less tolerant of water quality fluctuations.

3. Significant differences in physicochemical properties

Wide pH range: The pH value of wastewater from different sources varies greatly. Fermentation wastewater and DAC system wastewater are acidic (pH 3.0-6.0), while equipment cleaning wastewater and circulating cooling drainage may be alkaline (pH 8.0-11.0). After mixing, they need to be neutralized and adjusted before entering the subsequent treatment unit.

Medium to low biodegradability: The BOD₅/COD ratio of most chlorol production wastewater is between 0.2 and 0.4, which is considered medium to low biodegradability. Among them, the BOD₅/COD ratio of electro-methanol wastewater is only 0.15-0.25, with a high proportion of recalcitrant organic matter. Pretreatment is required to improve biodegradability before biological treatment.

Containing high salt or heavy metals: The circulating cooling drainage and electrolytic cell cleaning wastewater of the electro-methanol production route contain high salt (TDS 5000-10000mg/L) and trace heavy metals (Ni, Fe); the wastewater of the biomass route contains a small amount of heavy metals (from the soil carried by the raw materials). High salt and heavy metals will further inhibit microbial activity and increase the difficulty of treatment.

V. Wastewater Treatment Process

Considering the core characteristics of chloramphenicol wastewater—"complex composition, large fluctuations in water quality, high toxicity, and moderate to low biodegradability"—a three-stage combined process of "pretreatment - main treatment - advanced treatment" is required to ensure that the effluent meets discharge standards (meeting the "Emission Standard of Pollutants for Petrochemical Industry" GB 31571-2015 or stricter local standards). Some process routes can achieve water reuse, as detailed below:

1. Pretreatment stage: Detoxification, impurity removal, desalination, and conditioning to solidify the biochemical foundation.

The core objective of pretreatment is to remove suspended solids and toxic and harmful substances, adjust water quality (pH, temperature), improve the biodegradability of wastewater, and prevent subsequent treatment units from being impacted.

Physical pretreatment: A combined process of "bar screen + sedimentation tank + dissolved air flotation tank" is adopted. The bar screen removes large suspended solids (such as straw fragments and silt); the sedimentation tank (inclined tube sedimentation tank or horizontal flow sedimentation tank) removes fine suspended solids, with an SS removal rate of over 80%; the dissolved air flotation tank removes oil, tar and fine suspended particles from the wastewater, further reducing SS and some organic matter, with a COD removal rate of approximately 10%-15%.

Chemical pretreatment: For acidic or alkaline wastewater, acid-base regulators (such as NaOH, H₂SO₄) are added to the neutralization tank to adjust the pH value to 6.5-8.5; for wastewater containing toxic organic compounds such as phenols and aldehydes, advanced oxidation technologies are used for detoxification and degradation. Common processes include Fenton oxidation (Fe²⁺+H₂O₂), iron-carbon micro-electrolysis, and ozone catalytic oxidation, which can reduce the concentration of phenols to below 50 mg/L, the concentration of aldehydes to below 50 mg/L, and the BOD₅/COD ratio to above 0.35, laying the foundation for biological treatment; for high-salinity wastewater (such as wastewater from electro-methanol circulating cooling), nanofiltration (NF) or reverse osmosis (RO) is used for pre-concentration to reduce the inhibitory effect of salts on subsequent biological treatment.

Targeted pretreatment: Cyanide-containing wastewater from biomass gasification is treated with alkaline chlorination (in two steps: CN⁻+ClO⁻+H₂O→CNCl+2OH⁻; CNCl+2OH⁻→CNO⁻+Cl⁻+H₂O), achieving a cyanide removal rate of over 99%; Amine-containing wastewater from electro-methanol production is treated with stripping (adjusting pH to 10-11, temperature 40-50℃) to remove organic amines, achieving a removal rate of approximately 80%-90%.

Desalination pretreatment: For wastewater with TDS > 3000 mg/L, such as circulating cooling drainage from electro-methanol production and high-salt cleaning wastewater, the following processes are adopted: "nanofiltration (NF) + reverse osmosis (RO) pre-concentration" or "MVR evaporation crystallization pre-separation".

Nanofiltration (NF) can retain high-valence salts and some recalcitrant organic matter, reducing the TDS of wastewater to below 3000 mg/L (the safe threshold for microbial tolerance), and the permeate can be directly introduced into the subsequent biological treatment system. Reverse osmosis (RO) further concentrates the nanofiltration concentrate, raising the TDS to 15000-20000 mg/L, or directly uses MVR evaporation and crystallization process to separate salts. The crystallized salt can be recycled as an industrial raw material or disposed of in accordance with hazardous waste regulations, thus avoiding the inhibition of the biological treatment system by high salt from the source.

2. Main treatment stage: Degradation of organic pollutants and nitrogen and phosphorus, the core emission reduction stage.

The main treatment is biological treatment, and the "anaerobic + aerobic" combined process is used for high-concentration, refractory wastewater to adapt to water quality fluctuations and high-concentration pollutant removal needs.

Anaerobic biological treatment: For high-concentration COD wastewater (COD > 10000 mg/L, such as fermentation separation wastewater and gasification phenol-containing wastewater), the UASB (Upflow Anaerobic Sludge Blanket) or IC (Internal Circulation Anaerobic Reactor) process is adopted. Under the action of anaerobic microorganisms, macromolecular organic matter is decomposed into methane, CO₂, etc., with a COD removal rate of 60%-70%, which significantly reduces the load of subsequent aerobic treatment. The reactor operating temperature is controlled at 35-38℃ (mesothermal anaerobic), the residence time is 12-24 hours, and it has strong resistance to shock loads and can adapt to COD concentration fluctuations of ±30%.

Wastewater Treatment Project of Fengyuan Group Yukang New Materials Co., Ltd.

Aerobic biological treatment: Anaerobic effluent enters the aerobic treatment system, employing a combined "A/O (anaerobic-aerobic) + MBR (membrane bioreactor)" process. The A/O process removes ammonia nitrogen through nitrification and denitrification (removal rate exceeding 90%), while the MBR process utilizes the membrane's retention capacity to achieve efficient separation of sludge and water, enhancing the degradation of organic matter by microorganisms, achieving a COD removal rate exceeding 85%.

Special treatment: For wastewater with extremely poor biodegradability, such as that from electro-methanol (BOD₅/COD < 0.2), a hydrolysis acidification tank is added between the anaerobic and aerobic processes to decompose recalcitrant organic matter into easily degradable small-molecule organic matter, further improving biodegradability; For wastewater with high ammonia nitrogen (ammonia nitrogen > 300 mg/L), a "short-cut nitrification-denitrification" process is adopted to shorten the reaction process and reduce energy consumption and carbon source dosage.

3. Deep processing stage: Optional, set as needed.

Advanced treatment will only be activated in the following scenarios, primarily addressing the needs of "strict emission standards" or "water resource reuse," and adapting to the environmental upgrade requirements of green alcohol projects. If the green alcohol production enterprise is located within a chemical industrial park, and the wastewater undergoes "pretreatment + main treatment" within the plant, the water quality meets the acceptance standards of the park's wastewater treatment plant and can be directly discharged into the park's wastewater treatment plant for subsequent centralized treatment, without the need to build an advanced treatment unit:

Scenario 1: If special emission limits need to be met (such as COD≤50mg/L, ammonia nitrogen≤5mg/L) or stricter local environmental protection requirements: Add "ozone-activated carbon (O₃-BAC)" or "UV-Fenton" process to deeply degrade the residual recalcitrant organic matter after the main treatment, and further increase the COD removal rate by 30%-40% to ensure that the effluent meets the standards stably.

Scenario 2: Water reuse needs exist (e.g., the project is located in a water-scarce area, or a circulating cooling water system is required): A dual-membrane process of "ultrafiltration (UF) + reverse osmosis (RO)" is added. Ultrafiltration removes suspended solids, colloids, and residual microorganisms from the water, ensuring the stability of the reverse osmosis membrane operation; reverse osmosis deeply removes dissolved organic matter, salts, and trace heavy metals, with product water TDS ≤ 100 mg/L, which can be directly used as supplementary water for circulating cooling water or for landscaping, achieving a reuse rate of 60%-70%; reverse osmosis concentrate is returned to the pretreatment desalination unit for recycling, achieving near-zero wastewater discharge.

In conclusion, the decarbonization trend in shipping presents a market opportunity worth hundreds of billions of yuan for the green alcohol industry. The implementation of 173 newly built and planned projects nationwide requires not only technological breakthroughs but also robust environmental compliance support. Green alcohol wastewater is complex in composition, highly toxic, and difficult to treat, directly impacting project commissioning progress and long-term operating costs. Therefore, choosing a professional environmental partner is crucial.

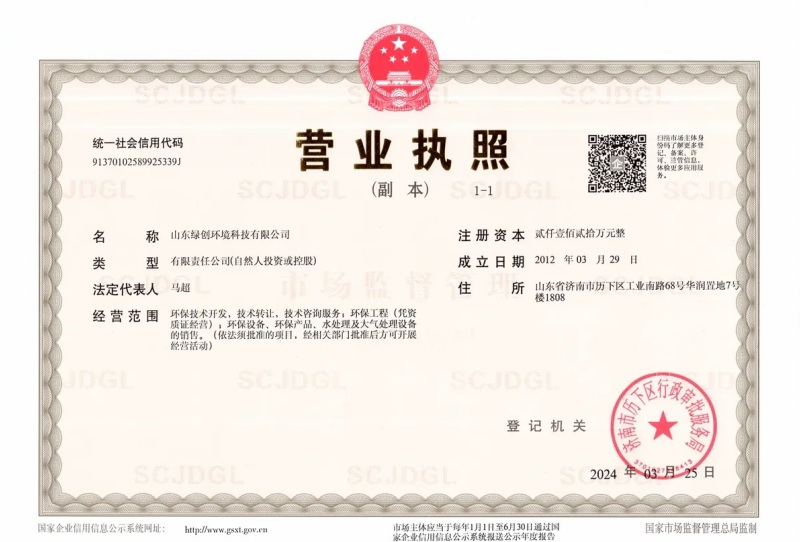

For over a decade, Green Creation has been dedicated to the technological research and engineering practice of high-concentration wastewater from petrochemical, pharmaceutical, pesticide, and fine chemical industries. It has developed comprehensive treatment models for challenging wastewater, including decarbonization, nitrogen removal, and ring-breaking/chain breaking. With over 300 wastewater treatment projects completed, its customer referral rate exceeds 80%. Clients include state-owned enterprises such as Sinopec, China Chengda, Shenghong Group, Shandong Energy, Lunan Chemical, Lanfan Chemical Group, and Green Power Pesticides, as well as leading private enterprises and listed companies. Green Creation has accumulated extensive experience in chemical wastewater treatment, enabling it to treat specific pollutants in a graded and differentiated manner, ensuring compliant discharge and stable operation of wastewater treatment while achieving high efficiency and cost reduction.

With the construction of green alcohol projects in full swing, if you are struggling to select the right wastewater treatment facilities for your green alcohol project, please call the number on the card below for consultation. We will provide you with free water quality diagnosis and help you customize a suitable solution, ensuring that every penny of your investment is well spent!

- Previous : What are the advantages of ammonia oxidation denitrification process in wastewater treatment?

- Next : 80,000 buyers will gather in Jinan, and thousands of exhibitors will explore business opportunities. The 16th International Bio-fermentation Exhibition in 2026 cordially invites you to attend!