Introduction to corn starch production wastewater treatment

1. Corn starch production technology

The cornstarch production process usually includes the following steps:

Raw material cleaning: Use methods such as screening and winnowing, and use equipment such as vibrating screens, specific gravity stone removers, permanent magnet drums, and wheat washing machines to remove large, medium, and small debris, side stones, magnetic metal impurities, and soil in corn. , dust, etc. to ensure safe production and product quality.

Soaking: Usually several or even dozens of metal tanks are used, connected together by pipes, and the soaking water is circulated between the tanks with the help of a water pump to achieve counter-current soaking. During soaking, an appropriate amount of sulfur dioxide will be added to the water. Its content is generally between 0.15% and 0.2%. At this time, the pH value of the solution is about 3.5. The soaking temperature is controlled at 50-55°C and the soaking time is 40-60 hours.

Coarse crushing: Most of the time use a disc crusher to break the soaked corn into more than 10 small pieces to separate the germ. Coarse crushing can be done in two times. The first time is broken into 4-6 pieces to separate the germ. The second time is to separate the germ. Then break it into more than 10 pieces to make all the germs fall off.

Germ separation: You can use equipment such as a germ separation tank or a hydrocyclone separator to separate the germ from the corn pieces. The hydrocyclone separator is made of nylon and has a small footprint, large production capacity, and high separation efficiency, which can reach More than 95%.

Grinding: The mixture of corn pieces and part of the starch after the germ has been separated, is ground twice.headThe first time is grinding with a hammer mill or universal grinder. After screening the starch milk, the second time is grinding with a sand disc starch mill or stone mill to destroy corn cells, free starch granules, and remove fiber and bran. separate.

Starch screening: Use screening equipment such as hexagonal screen, flat shaking screen, curved screen and centrifugal screen to separate starch from coarse and fine residue. Screening of coarse and fine residue requires an appropriate amount of clean water. The water temperature is 45-55°C and contains 0.05% sulfur dioxide. , pH is about 4.3-4.5.

Protein separation and starch cleaning: Generally, a centrifuge or launder is used to separate proteins. The separated crude starch milk is cleaned with a hydrocyclone, usually with a 9-14 stage hydrocyclone to reduce the protein content in starch.

Centrifugal separation and drying: Send the starch milk into a centrifuge for dehydration to obtain wet starch with a moisture content of 45%. The wet starch can be shipped as a finished product, or it can be further dried to reduce the moisture content of the starch to a balance of 12% Moisture, dried starch granules are screened and packaged before leaving the factory as finished dry starch.

2. Sources of corn starch production wastewater

Raw material soaking wastewater: When soaking corn, sulfurous acid, etc. are added to soften the corn kernels. The soluble proteins, sugars, and minerals in the corn are dissolved, resulting in a high concentration of organic pollutants in the wastewater.

Raw material washing wastewater: When the soil and impurities on the corn surface are washed, the sediment and a small amount of organic components flow away with the water to form wastewater. Starch separation wastewater: When starch is separated, the equipment is rinsed with water, and residual starch, protein, fiber and additives are mixed into the water to produce this wastewater.

Starch refining wastewater: Refined starch needs to be washed multiple times to remove impurities. The washed proteins, fats, sugars, etc. increase the organic content of the wastewater.

Equipment cleaning wastewater: Crusher, centrifuge and other equipment need to be cleaned during maintenance and cleaning. Residual raw materials, starch and additives flow into the wastewater system with the cleaning water.

Workshop floor washing wastewater: Corn and starch are spilled on the workshop floor. During washing, these substances are washed into the drainage pipes to form wastewater.

3. Characteristics of corn starch production wastewater

Large amount of wastewater generation: The corn starch production process uses a large amount of water, generally 10-20m³ wastewater/t cornstarch, resulting in a large amount of wastewater.

High concentration of organic matter: Wastewater contains a large amount of starch, sugar, protein, cellulose and other organic matter. The COD (chemical oxygen demand) concentration is usually 500-30000mg/L, and the BOD (biochemical oxygen demand) concentration is also high.

High nitrogen and phosphorus nutrients: Contains a certain amount of nitrogen and phosphorus elements, which can provide nutrients for the growth of microorganisms.

High suspended solids content: The suspended solids concentration is generally 400-10000mg/L.

Wastewater is acidic: Sulfurous acid solution is often added during the corn soaking process, causing the wastewater to be acidic, with a pH value usually between 4-6.

Good biodegradability: The ratio of BOD to COD is high, so it is suitable for biological treatment methods.

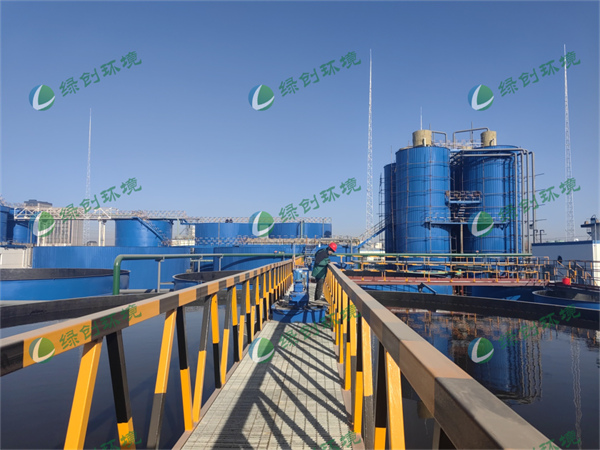

4. Company cases

Jinzhou Yuancheng Biotechnology Co., Ltd. Wastewater Treatment Renovation and Expansion Project Site If you have any needs for corn starch wastewater treatment, please feel free to call us at the number on the card below. We will wholeheartedly provide you with professional consulting services and customized solutions, and work together to protect green waters and green mountains!