Introduction to soy protein isolate production wastewater treatment

Soy protein isolate is to extract soybean meal (removing oil and water-soluble non-protein components) in an alkaline solution under low temperature conditions, and then precipitate, wash, and dry to obtain a protein powder with a protein content of more than 90%. Its structure and properties are basically Replace pure soy protein. There are nearly 20 kinds of amino acids in soy protein isolate, and they contain essential amino acids for the human body. It is rich in nutrients and contains no cholesterol. It is one of the few plant proteins that can replace animal protein.

However, the production process of soy protein isolate is associated with large amounts of wastewater. This type of wastewater has complex components and is rich in organic matter, nitrogen and phosphorus nutrients and suspended solids. If it is directly discharged without proper treatment, it will cause serious pollution to surrounding water bodies and soil. Therefore, effective treatment of soy protein isolate production wastewater is not only a necessary measure for enterprises to fulfill their environmental protection responsibilities and promote the green transformation of the industry, but also an urgent need to protect the ecological environment and build a solid foundation for sustainable development.

1. Soybean protein isolate production technology

Alkali-soluble acid precipitation method: add water or alkali solution to the low-temperature desolubilized soybean flour to extract the soluble substances together with the soybean protein, and filter to remove the insoluble substances. Acid is added to adjust the pH of the extract to about 4.5, and the protein is precipitated and separated from the soluble components. The precipitate is washed with water and dried to obtain the finished product.

Ultrafiltration membrane method: Using the screening effect of the ultrafiltration membrane, under a certain pressure, the macromolecular proteins in the soy protein extract are separated from small molecule impurities, salts, etc., thereby obtaining high-purity soy protein isolate.

Ion exchange method: Through the exchange reaction between the ion exchange resin and the ions in the soy protein extract, impurity ions are removed, and the soy protein is purified and concentrated to obtain high-quality soy protein isolate.

2. Sources of wastewater from soybean protein isolate production

Soy protein isolate production wastewater mainly comes from the following key production links:

1. Alkali dissolution step In the alkali dissolution process, in order to dissolve soybean protein, a large amount of alkali solution (such as sodium hydroxide) will be added. When the protein is fully dissolved, remaining lye will remain in the solution. At the same time, some soluble impurities in soybean raw materials will also be dissolved in the solution. After subsequent filtration and other operations of this part of the solution, the remaining liquid containing alkali and impurities becomes part of the wastewater. For example, excess alkali will increase the pH value of wastewater and contain unreacted alkali and impurities such as sugars and minerals leached from soybeans.

2. In the filtration step, the alkali-dissolved mixed liquid passes through filtration equipment (such as plate and frame filter, centrifugal filter, etc.) to remove insoluble residues (such as soybean skins, undissolved soybean flour particles, etc.). During the filtration process, a large amount of water is used to clean the filter equipment and rinse the residue. This water will carry the filtered residue, residual alkali solution and a small amount of dissolved protein, forming wastewater.

3. Acid precipitation step During the acid precipitation process, acid (such as hydrochloric acid) needs to be added to adjust the pH value and precipitate the protein. Not all of the added acid will participate in the reaction, and unreacted acid will remain in the solution. Moreover, after protein precipitation, the supernatant contains acids, salts (generated by acid-base reactions), incompletely precipitated proteins, small molecule sugars and other impurities. This supernatant becomes wastewater after separation.

4. In the water washing step, in order to remove acids, salts and other small molecule impurities in the precipitated protein, it is necessary to wash repeatedly with clean water. The washed water contains a large amount of acid, salt, impurities and a small amount of protein. This part of water directly constitutes an important part of the production wastewater. The more times you wash, the greater the amount of wastewater produced.

5. Equipment cleaning Equipment used in the entire soy protein isolate production process, such as reaction kettles, filtering equipment, drying equipment, etc., need to be cleaned after the end of production or when changing product batches. The water used for cleaning equipment will take away the remaining proteins, acid and alkali solutions, salts and other impurities on the surface of the equipment. This cleaning water containing a variety of pollutants is a major source of wastewater. For example, the remaining proteins and acid and alkali liquids on the walls of the reactor will enter the cleaning water during the cleaning process, making the composition of the wastewater more complex.

6. Ultrafiltration membrane cleaning (if ultrafiltration membrane method is used) If ultrafiltration membrane method is used for separation during the production process, the ultrafiltration membrane will be blocked by impurities after being used for a period of time. In order to restore membrane performance, ultrafiltration membranes need to be cleaned regularly. Chemical cleaning agents, such as acids, alkalis, surfactants, etc., are used when cleaning ultrafiltration membranes. These cleaning agents are mixed with the washed proteins and impurities to form wastewater containing chemical cleaning agents, proteins and impurities.

3. Water quality characteristics of soybean protein isolate production wastewater

1. High organic matter concentration. During the production process of soy protein isolate, since the raw soybeans themselves are rich in protein, polysaccharides and other organic substances, a large amount of organic matter enters the wastewater during alkali dissolution, acid precipitation, water washing and other processes, resulting in chemical oxygen demand of the wastewater. (COD) and biochemical oxygen demand (BOD) values are extremely high. Generally speaking, its COD concentration can be as high as 10000-20000mg/l, and its BOD concentration can also reach about 5000-8000mg/l.

2. High suspended solids content. Many fine solid particles will be produced during the production process, such as incompletely dissolved soybean residues, fibers, etc. These substances are suspended in the wastewater, making the suspended solids (SS) content in the wastewater high. Usually in Between 1500-7400mg/l.

3. Good biodegradability. The organic substances in wastewater are mostly proteins, polysaccharides, etc. These substances are easily decomposed and transformed under the action of microorganisms. The ratio of BOD to COD is generally between 0.4-0.7, and the biodegradability is good. , suitable for purification using biological treatment methods.

4. Rich in nutrients. In addition to organic matter, wastewater also contains a large amount of nitrogen, phosphorus and other nutrients. For example, the total nitrogen content can reach 500-1000mg/l. These nutrients provide good conditions for the growth and reproduction of microorganisms, but If it is discharged directly without treatment, it will cause eutrophication in the receiving water body and cause damage to the ecological environment.

5. Higher temperature and lower pH value. Some process links in the production process will increase the temperature of the wastewater. Generally, the water temperature is between 50-60℃. At the same time, due to the use of acid precipitation and other processes, the wastewater is usually acidic and the pH value is low. The value is around 4-5. This high temperature and low pH The characteristics of wastewater with poor value will not only affect the activity of microorganisms during wastewater treatment, but also easily lead to spoilage and deterioration of wastewater during storage and transportation, produce unpleasant odors, and release harmful gases such as hydrogen sulfide.

6. Large fluctuations in water quality and quantity. Due to differences in raw material varieties, production processes, production scale, management levels and other factors, the quality and quantity of wastewater will fluctuate greatly, which brings certain challenges to the stable operation of the wastewater treatment process. This feature needs to be fully taken into consideration when designing and operating the wastewater treatment system, and corresponding adjustment and control measures should be taken to ensure the stability of the treatment effect.

4. Case introduction

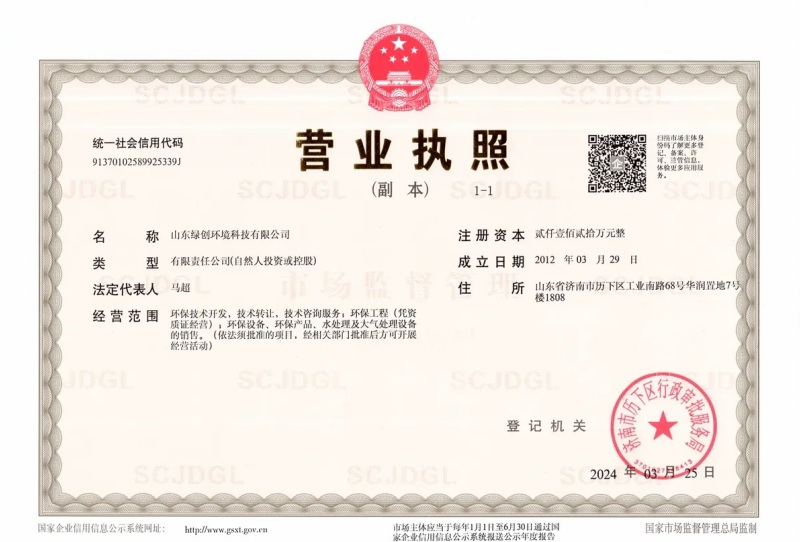

Tongyu County Yifahe Soybean Products Co., Ltd. was established on May 15, 2001 and is located in Tongyu County Economic Development Zone, Baicheng City, Jilin Province. The company mainly focuses on the deep processing of soybeans, and its leading product is soybean protein isolate, which is an important raw material for meat product processing. The current production capacity reaches 16,000 tons, and the products are exported to Southeast Asia, Russia, Kazakhstan, Ukraine, Finland, etc.

Our company is responsible for the design, construction and commissioning of the soy protein wastewater treatment project of Tongyu County Yifahe Soybean Products Co., Ltd. The daily water treatment capacity of this project is 2000m³/d, and the main process adopts "pretreatment + LIC anaerobic reactor + AnDeN ammonia oxidation "Denitrification + phosphorus removal" process, the effluent COD is less than 150mg/L, and the ammonia nitrogen is less than 15mg/L. Among them, the AnDeN ammonia oxidation process is independently developed by our company based on the principle of anaerobic ammonium oxidation. It breaks through the technical barriers that make anaerobic ammonium oxidation difficult to control. It perfectly realizes biological denitrification without adding ammonia oxidizing bacteria. Quick start of the system, the picture below shows the action process of anaerobic ammonium oxidizing bacteria in this project.

The sewage treatment station of this project has been in stable operation for more than a year. If you have any needs for wastewater treatment from soy protein isolate production, please call the phone number below for consultation.