Introduction to Beet Sugar Wastewater Treatment

The sugar industry is the foundation of the food industry, and it is also the raw material pillar of many industries such as papermaking, chemical industry, and fermentation. It plays an important role in the national economy. As an important branch of the sugar industry, the large amount of wastewater generated in the production process of beet sugar will seriously pollute the environment if it is directly discharged without treatment. With the deepening of the "dual carbon" goals, achieving clean production and efficient wastewater treatment has become a core issue in the green transformation of the industry. This article will take you into the production process and wastewater treatment technology of beet sugar.

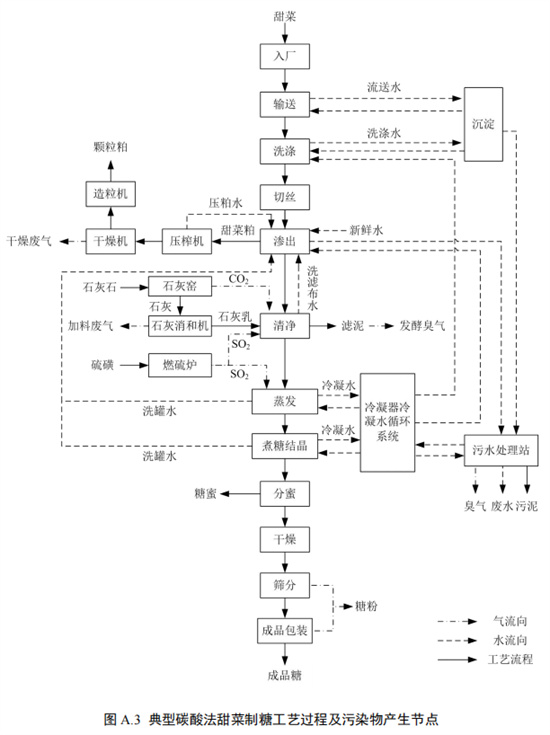

1. Introduction to Beet Sugar Production Process

The sugar beets are transported from the sugar beet cellar to the workshop, and after pre-treatment such as impurity removal and washing, they are cut into shreds and sent to the percolator. The percolating juice is purified to remove non-sugar substances. The purified sugar juice is decolorized by sulfur bleaching and sent to the multi-effect evaporator to be concentrated into syrup. The syrup is then boiled, crystallized, separated, dried, screened, and the finished sugar is packaged.

2. Beet sugar production process and wastewater sources

01Beet pretreatment section

Beet sugar production can be divided into six stages, namely beet pretreatment, sugar exudation (extraction), juice purification, evaporation, sugar boiling and honey separation, drying and packaging.

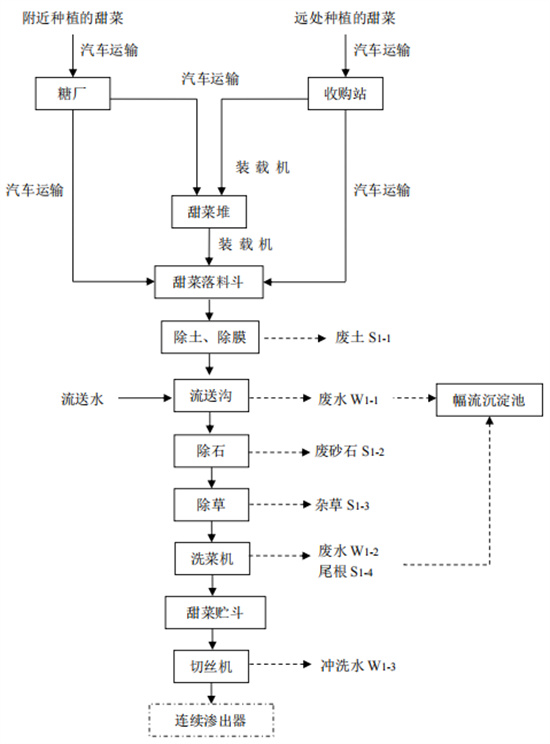

Pretreatment includes purchase, storage and transportation, soil and film removal, stone removal, weeding, beet lifting, vegetable washing and shredding. In the soil and film removal stages, the beets coming out of the soil remover will enter the flow ditch, and will be hydraulically transported to the stone remover and weed remover before entering the vegetable washer. After washing, the clean beets will enter the shredder, which will cut the beets into shreds of a certain specification and send them to the extractor.

In this section, wastewater discharge point 1 is the beet delivery water in the beet delivery ditch, which mainly consists of silt and beet tubers; discharge point 2 is the vegetable washing water in the vegetable washing machine, which mainly consists of sugar and weeds; discharge point 3 is the flushing water in the shredder, which mainly consists of sugar. The delivery water and vegetable washing water are partially reused after sedimentation, and the shredder flushing water is discharged into the sewage treatment station.

Beet pretreatment process and pollution generation links

02Sugar seepage section

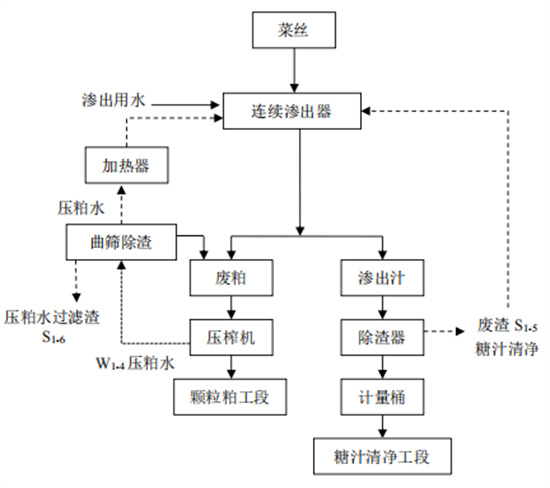

The percolation section is designed to efficiently extract sugar from beets, reduce sugar loss and improve the purity of the percolation juice. After pre-treatment, the beets are shredded and weighed and then sent to the continuous percolator, which moves in countercurrent with 45-55℃ hot water. The sugar is transferred to the water, the percolation juice is extracted at the front end, and the waste residue is discharged at the tail end.

The wastewater in this section mainly comes from the waste meal water of the waste meal press, and its main components are sugar and beet pulp. This wastewater is returned to the extractor after the pulp is removed.

Seepage process flow and pollution generation links

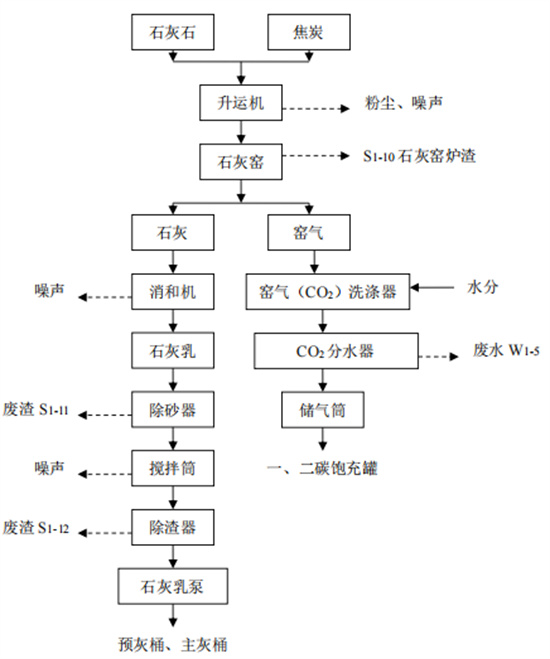

03Sugar juice purification and lime kiln section

The process of removing non-sugars from the exudate is called juice purification. At present, my country's beet sugar factories use the mature double carbonation method. In this stage, only filter mud is produced in the one-carbon and two-carbon filters, and thin sugar mud is produced in the thin juice bag filter. The main components are shredded vegetables and beet residues, and no wastewater is generated.

The CO2 used in sugar juice purification is produced by calcining limestone (CaCO3) in a lime kiln. In this stage, cellar gas scrubber produces cellar gas washing wastewater, which can be sent to the coal yard for dust suppression.

Lime kiln workshop process flow and pollution generation process diagram

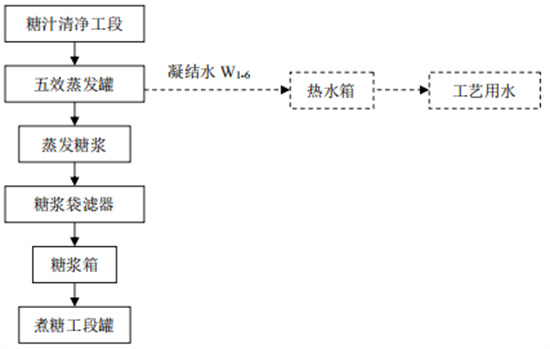

04Sugar juice evaporation and sugar making process

The thin juice obtained after purification has a low concentration and must be evaporated into thick juice before cooking sugar. The thin juice is concentrated into thick juice through multi-effect evaporation, which is called evaporated syrup. After passing through the syrup bag filter, it is sent to the sugar cooking process. Modern sugar factories all use multi-effect evaporators with steam as heat source. The wastewater generated at this stage is the condensed water at the end of evaporation produced by the multi-effect evaporator, which is all reused.

Evaporation process flow and pollution generation process diagram

The syrup is boiled, crystallized (one paste, two pastes, three pastes) and divided into honey several times to obtain the finished product one sugar (white sugar); the two or three sugars are dissolved back and then cooked, and the waste honey cannot recrystallize because it contains non-sugar content and is discharged as a by-product. The entire process forms a closed-loop circulation of sugar and the discharge of waste honey, and no waste water is produced in the sugar-forming section.

05Dry packaging

Once the granulated sugar has been dried and screened, and the quality meets national standards, it will be weighed, packaged and put into storage as a finished product. During the operation of the beet sugar project, in addition to the above-mentioned sources, the sources of wastewater also include office and domestic sewage, canteen wastewater, and ground cleaning wastewater.

3. Characteristics of wastewater

High organic matter concentration: Beet sugar wastewater contains a large amount of organic matter such as sugars (sucrose, glucose, fructose, etc.), pectin, cellulose, protein, amino acids, etc., which leads to extremely high chemical oxygen demand (CODcr) and biochemical oxygen demand (BOD₅) of the wastewater, among which CODcr can reach 12000mg/L.

High suspended solids: The wastewater contains mud and sand brought in during the beet raw material cleaning process, beet skin debris, fiber impurities, as well as sugar residues and flocs produced in the sugar production process. The suspended solids concentration is usually 3000~4000 mg/L, or even higher.

Anaerobic treatment is prone to foaming: the natural saponins and protein degradation products in sugar beets are highly foaming, which leads to frequent foaming during the operation of anaerobic reactors. This requires a combination of mechanical defoaming and chemical control.

High nitrogen content in wastewater: Beet sugar wastewater has a high nitrogen content because beets themselves contain natural nitrogen-containing components such as protein, amino acids, and betaine, which seep into the wastewater as they are crushed during sugar production. In addition, the decomposition of by-products such as waste molasses and sugar residues and microbial metabolism will also release nitrogen, causing the total nitrogen to reach 100~200mg/L.

The phosphorus content in the wastewater is relatively high: mainly because the sugar beet raw materials contain natural phytic acid, phospholipids and other phosphorus-containing organic matter, which are dissolved after sugar making and crushing; phosphorus-containing flocculants (such as phosphates) or detergents may be added in the process; waste molasses, sugar residues and other by-products ferment and decompose to release phosphorus; microbial metabolism and improper sludge treatment will also increase the phosphorus load.

The production cycle is strong and the water volume fluctuates dramatically: wastewater is concentrated in the 4-5 month production period, with a sharp increase in a short period of time and a sharp drop in water volume in the non-seasonal period, requiring the treatment system to have shock resistance and flexible operation capabilities.

Water volume control depends on process optimization, and has great potential for water saving: instantaneous discharge during production peaks can easily impact the biological system, requiring buffering in a regulating pool and enhanced pretreatment. The wastewater from traditional processes is about 1.5~2m³/t of beets, and efficient water circulation (such as reuse of vegetable washing water) can be reduced to less than 0.4m³/t, significantly reducing discharge pressure.

4. Wastewater treatment process

The wastewater generated by each production process of beet sugar is collected and discharged into the sewage treatment plant. Generally, the primary treatment + secondary treatment technology is adopted to meet the requirements of the "Sugar Industry Water Pollutant Discharge Standard" (GB21909-2008).

01Primary treatment technology

This technology mainly removes suspended matter and silt from beet sugar wastewater, including screens, regulating tanks and sedimentation tanks. After the suspended matter is removed by the screen, the wastewater enters the regulating tank, and after the water quality and water volume are adjusted in the regulating tank, it enters the sedimentation tank. In the sedimentation tank, suspended matter with a density greater than that of the wastewater is removed by natural sedimentation by gravity. The residence time of the wastewater in the regulating tank can be determined according to the influent water quality and water volume, and the effluent water quality must meet the requirements for stable operation of subsequent secondary treatment. The sedimentation tanks used in the primary treatment include vertical flow, horizontal flow, radial flow and inclined tube (plate) sedimentation tanks. When the amount of wastewater is large, radial flow sedimentation tanks should be used.

The surface hydraulic load of vertical flow, horizontal flow and radial flow sedimentation tanks is generally 1.5~3.0m³/(m²·h), and the surface hydraulic load of inclined tube (plate) sedimentation tank is generally 2.5~5.0m³/(m²·h). Through sedimentation, the removal rate of CODcr, BOD₅, total nitrogen and total phosphorus in wastewater is generally 10%~25%, and the SS removal rate is generally 40%~70%.

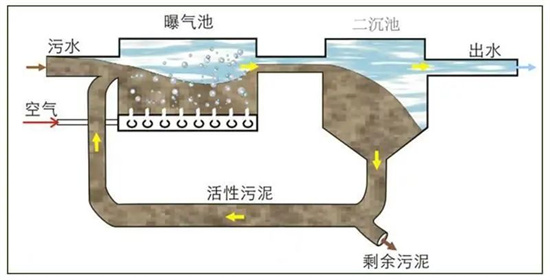

02Secondary treatment technology

This technology mainly removes organic matter from beet sugar wastewater, including anaerobic biological treatment technology and aerobic biological treatment technology. Anaerobic biological treatment technologies mainly include hydrolysis acidification treatment technology and upflow anaerobic sludge bed treatment technology. Aerobic biological treatment technologies mainly include conventional activated sludge method, sequencing batch activated sludge method, oxidation ditch, biological contact oxidation method and biological rotary disc method. When the CODcr concentration in beet sugar wastewater is less than 500mg/L, aerobic biological treatment technology is generally used for secondary treatment; when the CODcr concentration is 500~1500mg/L, hydrolysis acidification + aerobic biological treatment technology is generally used for secondary treatment; when the CODcr concentration is greater than 1500mg/L, upflow anaerobic sludge bed + aerobic biological treatment technology is generally used for secondary treatment.

2.1 Anaerobic biological treatment technology

Hydrolysis acidification treatment technology: This technology utilizes the action of anaerobic or facultative bacteria in the hydrolysis acidification stage to hydrolyze insoluble macromolecular organic matter in the wastewater into soluble organic matter. The removal rate of CODcr in the wastewater may not be very high, but it can significantly improve the biodegradability of the wastewater.

When the influent CODcr concentration is 500~1500mg/L and the hydraulic retention time is 3~6h, the CODcr removal rate is 20%~40% and the BOD₅ removal rate is 20%~40% when this technology is used to treat wastewater.

Anaerobic reactor: This technology uses a water distribution device to allow high-concentration wastewater to enter the sludge layer at the bottom of the sludge bed and the sludge suspension area in the middle and upper parts in turn. Under the action of anaerobic microorganisms in the sludge bed, high-concentration organic waste is degraded to generate biogas, and the CODcr and BOD₅ in the wastewater are greatly reduced, meeting the water inlet requirements of subsequent aerobic biological treatment technology. The volume load of the upflow anaerobic sludge bed at different temperatures varies greatly. When the temperature is 35~40℃, the CODcr volume load is 10~20kg/(m³.d), and the CODcr volume load is 3~5kg/(m³·d) under normal temperature conditions.

When the influent CODcr concentration is greater than 1500mg/L, the influent BOD₅/CODcr is greater than 0.3, and the SS content is less than 1000mg/L, the CODcr removal rate can reach 80%~90%, the BOD₅ removal rate can reach 70%~80%, and the SS removal rate can reach 30%~50% when this technology is used to treat wastewater.

2.2 Aerobic biological treatment technology

Conventional activated sludge method: This technology is suitable for treating low-concentration wastewater with high requirements for purification degree and stability. It has a stable process, high organic matter removal rate, and can effectively remove organic pollutants in wastewater. When the influent CODcr concentration is less than 500mg/L, the sludge concentration in the wastewater is 2~4g/L, and the hydraulic retention time is 6~20h, this technology can be used to treat wastewater, and the CODcr removal rate can reach 80%~90%, the BOD₅ removal rate can reach 70%~80%, and the SS removal rate can reach 30%~50%.

Sequential batch activated sludge process: This technology is suitable for treating wastewater with large fluctuations in water quality and water volume. It can effectively remove organic pollutants in wastewater and has good denitrification and phosphorus removal effects. Its main variant processes include periodic cycle activated sludge process, continuous and intermittent aeration process, alternating internal cycle activated sludge process, etc. When the influent CODcr concentration is less than 500mg/L, BOD₅/CODcr is greater than 0.3, the sludge concentration is 3~5g/L, and the hydraulic retention time is 8~20h, the CODcr removal rate of wastewater treated by this technology can reach 80%~95%, the BOD₅ removal rate can reach 80%~90%, the SS removal rate can reach 70%~90%, the ammonia nitrogen removal rate can reach 85%~95%, the total nitrogen removal rate can reach 60%~85%, and the total phosphorus removal rate can reach 50%~85%.

Oxidation ditch: This technology has stable wastewater treatment effect, strong impact load resistance, and can achieve biological denitrification. Its main processes include single-trough oxidation ditch, double-trough oxidation ditch, three-trough oxidation ditch, vertical surface aeration machine oxidation ditch and concentric centripetal flow oxidation ditch. The deformation process includes integrated oxidation ditch and microporous aeration oxidation ditch. When the influent CODcr is less than 500mg/L, BOD₅/CODcr is greater than 0.3, the sludge concentration is 2~4.5g/L, and the hydraulic retention time is 4~20h, this technology is used to treat wastewater, and the CODcr removal rate can reach 80%~90%, the BODs removal rate can reach 80%~95%, the SS removal rate can reach 70%~90%, the ammonia nitrogen removal rate can reach 85%~95%, the total nitrogen removal rate can reach 55%~85%, and the total phosphorus removal rate can reach 50%~75%.

Biological contact oxidation method: This technology is suitable for treating low-concentration wastewater with high effluent index requirements under low load. The CODcr removal rate is high when this technology is used to treat wastewater, and the ammonia nitrogen nitrification effect is strong. It also has a certain treatment effect on difficult-to-degrade organic matter. When the influent CODcr is less than 500mg/L, BOD₅/CODcr is greater than 0.3, SS is less than 500mg/L, and the hydraulic retention time in the packing area is 4~12h, the CODcr removal rate can reach 80%~90%, the BOD₅ removal rate can reach 80%~95%, the SS removal rate can reach 70%~90%, the ammonia nitrogen removal rate can reach 60%~90%, and the total nitrogen removal rate can reach 50%~80%.

Bio-rotating disc method: This technology does not require aeration and sludge return for wastewater treatment, and has a simple process flow and is easy to operate. When the influent CODcr is less than 500mg/L, BOD₅/CODcr is greater than 0.3, the edge linear speed of the bio-rotating disc is about 20m/min, and the hydraulic retention time is 0.6~3h, the CODcr removal rate can reach 70%~85%, the BOD₅ removal rate can reach 70%~90%, and the SS removal rate can reach 70%~90%.

Beet sugar wastewater treatment is a complex and important task that requires the comprehensive use of multiple treatment processes to achieve standard discharge of wastewater and effective utilization of resources. With increasingly stringent environmental protection requirements and continuous technological advancement, beet sugar wastewater treatment technology will continue to innovate and improve, safeguarding the green development of the beet sugar industry.

If you have any questions or needs about beet sugar production wastewater treatment technology, please feel free to contact us by calling the number on the card below.