Solutions to sludge expansion, floating, foaming and disintegration are all here!

1. Causes and solutions of sludge expansion

01Causes of sludge expansion

1.1 Expansion of filamentous bacteria

The filamentous bacteria in the activated sludge flocs overproduce, leading to expansion. The contributing conditions include low organic matter in the incoming water, too low F/M, insufficient microbial food; insufficient nitrogen and phosphorus in the incoming water; low pH value; too much dissolved oxygen in the mixed solution. Low, which cannot meet the needs; the inlet water fluctuates too much, which has an impact on microorganisms.

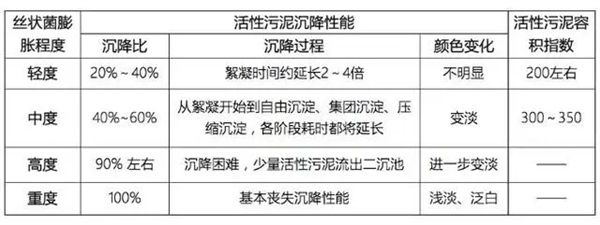

The degree of expansion of filamentous bacteria can be judged by the activated sludge settling performance and volume index:

1.2 Expansion of non-filamentous bacteria

Since the incoming water contains a large amount of dissolved organic matter, the sludge load is too high, and the incoming water lacks enough N, P, or insufficient DO (dissolved oxygen). The bacteria quickly absorb a large amount of organic matter into the body and cannot metabolize it. Decompose and secrete excess polysaccharides to the outside.

The molecules of these substances contain hydroxyl groups and are highly hydrophilic, making the activated sludge's bound water as high as 400% (normally about 100%), making it a sticky gel that cannot be separated in the secondary sedimentation tank.

Another type of expansion of non-filamentous bacteria is that the incoming water contains more poisons, causing bacterial poisoning. The bacteria cannot secrete a sufficient amount of sticky substances, cannot form flocs, and cannot be separated.

02Solution

In order to prevent sludge expansion, management operations should be strengthened first, and sewage water quality, dissolved oxygen in the aeration tank, sludge sedimentation ratio, sludge index and microscopic observation should be frequently tested. If any abnormality is found, measures should be taken promptly, such as increasing the air volume. , Drain mud in time, and take water in stages when possible to reduce the load of the secondary sedimentation tank.

For mild or moderate expansion of filamentous bacteria, you can adjust the pH by raising the pH and using an appropriate amount of fungicides. For high or severe expansion of filamentous bacteria, you can consider giving up treatment and re-culturing the tank with mud.

The expansion of non-filamentous bacteria is relatively simple, and the main method is to reduce the load or adjust the CNP ratio to solve it.

2. Causes and solutions for floating sludge

01Causes of floating sludge

Sludge floating mainly refers to sludge denitrification and floating. If the sewage stays in the secondary sedimentation tank for a long time, it will cause hypoxia (DO below 0.5 mg/L). The denitrifying bacteria will convert nitrate into ammonia and nitrogen. When ammonia and nitrogen escape, the sludge will absorb ammonia. Floating with nitrogen gas reduces the settleability of sludge.

02Solution

The phenomenon of sludge floating has nothing to do with the properties of activated sludge. It is only because bubbles are generated in the sludge that the density of the sludge is lower than that of water. Therefore, sludge floating should not be confused with sludge expansion. Specific solutions include:

2.1 Reduce the salt concentration of the incoming water and control the impact of high-load COD.

2.2 Accurately control the COD load in the aeration tank. Therefore, the amount of water entering the aeration tank must be controlled during operation. By accurately controlling the MLSS (recommended 6~8g/L) and the water inlet volume of the aeration tank, the COD load is controlled within an appropriate range of 0.2~0.4kg/(m3·d) to reduce the impact of sewage. If the sewage passes through a uniform If the COD concentration after the mass pool still exceeds the design standard, the sewage should be introduced into the accident pool for future treatment.

2.3 Improve the new sewage pretreatment process and control the sewage anaerobic and facultative acidification hydrolysis tanks are key steps to ensure the normal operation of the subsequent aeration tank. After the refractory organic matter in the sewage is degraded, the effluent of the aeration tank sewage can be guaranteed requirements, and also improves the settling performance of the secondary sedimentation tank.

The following measures should be taken: complete the transformation of the power distribution system of the submersible mixer, pump the sludge to the acidification tank as soon as possible, debug the acidification tank and domesticate the acidified sludge. The remaining sludge added at one time is about 1/5 of the tank volume, and the dosage is about 100m³, so that the concentration of the mixed liquid in the tank is 4-6g/L.

2.4 Control the dissolved oxygen concentration of the aeration tank, appropriately reduce the MLSS of the aeration tank, and basically control it within 10g/L. The corresponding dissolved oxygen concentration control should be adjusted in time according to the organic load of the incoming water.

2.5 Increase the sludge return flow, remove the remaining sludge in time, reduce the sludge concentration of the mixed liquid, shorten the sludge age, and reduce the dissolved oxygen concentration, but do not enter the digestion stage.

3. Bubble problem and its solution

01Bubble problem

1.1 Startup Bubble

In the early stages of activated sludge process operation, because the sewage contains some surface active substances, it is easy to cause surface foam. However, as activated sludge matures and these surface active substances are degraded by microorganisms, the foaming phenomenon will gradually disappear.

1.2 Denitrification foam

If the sewage plant performs nitrification reaction, denitrification will occur in the sedimentation tank or in places with insufficient aeration, producing nitrogen and other bubbles that will drive some sludge to float, causing foaming.

1.3 Biofoam

Due to the abnormal growth of filamentous microorganisms, the foam mixed with bubbles and floc particles is stable, continuous, and difficult to control.

Biological foam is very detrimental to the normal operation of the sewage plant: a large number of filamentous microorganisms appear in the aeration tank or secondary sedimentation tank, floating on the water surface, accumulating a large amount of foam, causing the concentration of organic matter and suspended solids in the effluent to increase, producing odor or Undesirable and harmful gases reduce the oxygen transfer efficiency of mechanical aeration, which may cause a large amount of surface foam to be generated during later sludge digestion.

02Solution

2.1 Spray water

This is a commonly used physical method. Reduce foam by spraying water or water beads to break up air bubbles floating on the surface of the water. The dispersed sludge particles partially regain their settling performance, but filamentous bacteria still exist in the mixed liquid, so the foaming phenomenon cannot be fundamentally eliminated.

2.2 Add defoaming agent

Biocides with strong oxidizing properties, such as chlorine, ozone and peroxide, can be used. There are also commercially available agents produced using polyethylene glycol and silicone, as well as mixed agents using ferric chloride and copper pickling liquid.

The effect of the agent can only reduce the growth of foam, but cannot eliminate the formation of foam. However, widely used fungicides generally have side effects. Excessive dosage or improper dosage will greatly reduce the number and total biomass of flocculating bacteria in the reaction tank.

2.3 Reduce sludge age

Generally, the residence time of sludge in the aeration tank is reduced to inhibit the growth of actinomycetes with a long growth period.

2.4 Return anaerobic digester supernatant

Experiments have shown that the method of returning the anaerobic digester supernatant to the aeration tank can control the formation of bubbles on the surface of the aeration tank.

2.5 Add special microorganisms

Some studies have suggested that some special strains of bacteria can eliminate the vitality of Nocardia bacteria, including the protozoan Nephrozoon spp. In addition, increasing predatory and antagonistic microorganisms can control some foam bacteria.

4. Causes and solutions for sludge disintegration

01Causes of sludge disintegration

Sludge disintegration is a phenomenon in which the water quality becomes turbid, the sludge flocs become finer, and the treatment effect deteriorates. The reasons leading to this abnormal phenomenon include: sludge poisoning, microbial metabolic function is damaged or disappeared, and sludge loses purification activity and flocculation activity.

In most cases, it is caused by accidental discharge of sewage, which should be overcome in production or partially pretreated. During normal operation, the volume of treated water or concentration of sewage is low for a long time, but the aeration volume is still at normal values, resulting in excessive aeration. , causing excessive self-oxidation of the sludge, a decrease in the flocculation performance of the bacterial jelly mass, and disintegration of the sludge. Further, the sludge may partially or completely lose its activity. At this time, the aeration volume should be adjusted, or only part of the aeration tank should be operated.

02Solution

Improper operation (such as excessive aeration) will destroy the balance of biological nutrients in activated sludge, reduce the amount of microorganisms and lose their activity, reduce the adsorption capacity, shrink the flocs and become dense, and some of them will become feathery sludge that is not easy to settle. , treatment of water turbidity, reduction of SV% value, etc.

When toxic substances are present in sewage, microorganisms will be inhibited and damaged, and the purification ability will decrease or stop completely, thereby rendering the sludge inactive.

Generally, the cause can be determined through microscopic observation. When an operational problem is identified, multiple indicators such as sewage volume, return sludge volume, air volume, sludge discharge status, and SV, MLSS, DO, NS, etc. should be checked and adjusted. When it is determined that toxic substances are mixed into sewage, it should be considered that this is the result of new industrial wastewater being mixed. The source needs to be identified and treated according to national discharge standards.

Source: Environmental Protection Platform